| View previous topic :: View next topic |

| Author |

Message |

Hursty

Joined: 29 Aug 2012

Posts: 319

Location: New Zealand

|

Posted: Tue Mar 12, 2013 8:25 pm Post subject: Posted: Tue Mar 12, 2013 8:25 pm Post subject: |

|

|

All though I have become quite attached to my little block of wood

I still am keen if someone comes up with a solution. I would prefer to keep my original stand standard so a remake works for me

_________________

Hursty from kiwi land  |

|

| Back to top |

|

|

oily

Joined: 05 Apr 2008

Posts: 4788

Location: worcestershire

|

Posted: Tue Mar 12, 2013 8:29 pm Post subject: Posted: Tue Mar 12, 2013 8:29 pm Post subject: |

|

|

PM you have

_________________

SB6 mk1 (project mega light, big bore)

Sb6 mk2 ( Big Bore)

Sb6 mk2 ( Restored)

Sb6R fighter

Sb6 or Sb7 WANTED |

|

| Back to top |

|

|

Vince186

Joined: 23 Mar 2012

Posts: 636

Location: Nijmegen (Netherlands)

|

Posted: Sat Apr 06, 2013 10:09 am Post subject: Posted: Sat Apr 06, 2013 10:09 am Post subject: |

|

|

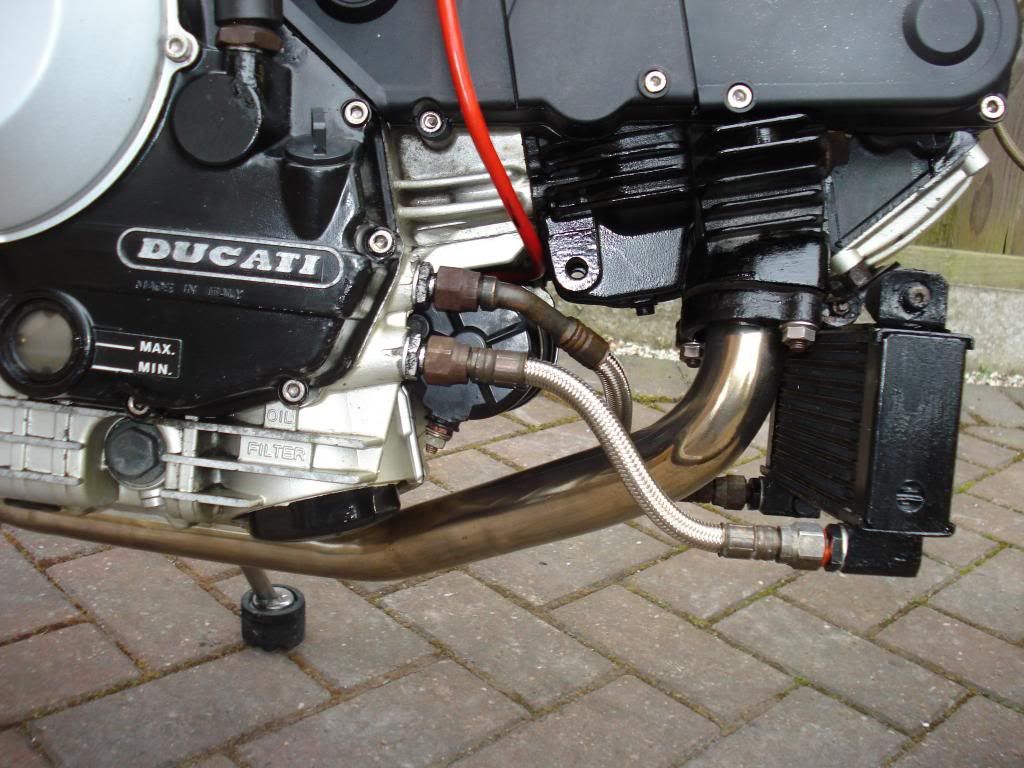

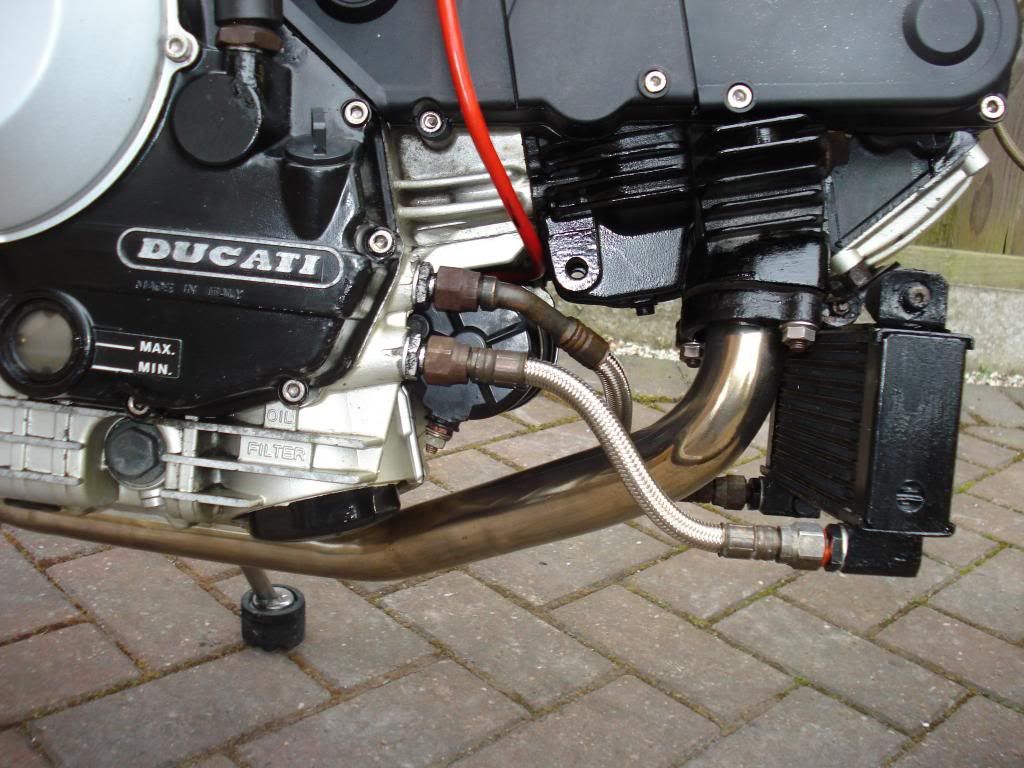

My side stands modification Ö. at least what I've made of it..

First carefully saw the weld seam. (Not too deep, about 4 mm)

Remove the upper half, thatís the part what to reuse.

If you do it carefully itís always possible to bring the side stand in its original condition.

I make me the parts as shown in the picture, I used 6082 T6 aluminium and stainless steel threaded rod.

Spring attachment is also stainless steel.

Assembled it and now I have a side stand thatís 25mm longer lighter and adjustable for an extra 20mm.

_________________

vince

A person who never made a mistake never tried anything new. Albert Einstein |

|

| Back to top |

|

|

SiBag

Joined: 03 Mar 2012

Posts: 251

Location: Cheshire

|

Posted: Sat Apr 06, 2013 10:23 am Post subject: Posted: Sat Apr 06, 2013 10:23 am Post subject: |

|

|

Nice work Vince,

I was thinking of doing similar but re-making the top section out of ally.

_________________

Si...

SB6..CCM R30...GSXR-750-M...RGV-250-VJ22.. GSX-1100-EFE Project....Harris Magnum II project...

If its got Ti#s or Wheels its gona give you trouble |

|

| Back to top |

|

|

Vince186

Joined: 23 Mar 2012

Posts: 636

Location: Nijmegen (Netherlands)

|

Posted: Sun Apr 07, 2013 6:00 pm Post subject: Posted: Sun Apr 07, 2013 6:00 pm Post subject: |

|

|

| SiBag wrote: |

Nice work Vince,

I was thinking of doing similar but re-making the top section out of ally. |

That was first mine idea also, but I wasnít sure what aluminium to use.

The top section is the part where higher forces are on.

This solution is easy to fabricate, you only need a lathe.

_________________

vince

A person who never made a mistake never tried anything new. Albert Einstein |

|

| Back to top |

|

|

oily

Joined: 05 Apr 2008

Posts: 4788

Location: worcestershire

|

Posted: Tue Apr 09, 2013 2:39 pm Post subject: Posted: Tue Apr 09, 2013 2:39 pm Post subject: |

|

|

Excellent work Vince

I'll be copying that when I can find time.....

_________________

SB6 mk1 (project mega light, big bore)

Sb6 mk2 ( Big Bore)

Sb6 mk2 ( Restored)

Sb6R fighter

Sb6 or Sb7 WANTED |

|

| Back to top |

|

|

Evilchicken0

Joined: 12 May 2010

Posts: 2996

Location: London

|

Posted: Tue Apr 09, 2013 2:54 pm Post subject: Posted: Tue Apr 09, 2013 2:54 pm Post subject: |

|

|

When I an alloy bottom yoke and steering stem made he used 7075T6

| Quote: |

| Hi, getting some more piccies - just got a load of FEA work done, using load case examples provided by an ex truimph chassis engineer, and also reverse engineered the loads using the SKF recommended safety factor back from the bearings. Using 7075T6 we are are well in, you'll be glad to know. We are about 10 times away from fatique load, using 2G as an assumption, and even that was presuming you and the bike and your missus and your luggage weighs 500kg! |

The side stand doesn't take the full weight of the bike although some people get onto them using the footpegs at shows.

_________________

Don't read everything you believe |

|

| Back to top |

|

|

Vince186

Joined: 23 Mar 2012

Posts: 636

Location: Nijmegen (Netherlands)

|

Posted: Wed Apr 10, 2013 7:10 am Post subject: Posted: Wed Apr 10, 2013 7:10 am Post subject: |

|

|

| oily wrote: |

Excellent work Vince

I'll be copying that when I can find time..... |

Finding time, I thought it is a matter of priorities

_________________

vince

A person who never made a mistake never tried anything new. Albert Einstein |

|

| Back to top |

|

|

Vince186

Joined: 23 Mar 2012

Posts: 636

Location: Nijmegen (Netherlands)

|

Posted: Wed Apr 10, 2013 7:12 am Post subject: Posted: Wed Apr 10, 2013 7:12 am Post subject: |

|

|

| Evilchicken0 wrote: |

When I an alloy bottom yoke and steering stem made he used 7075T6

| Quote: |

| Hi, getting some more piccies - just got a load of FEA work done, using load case examples provided by an ex truimph chassis engineer, and also reverse engineered the loads using the SKF recommended safety factor back from the bearings. Using 7075T6 we are are well in, you'll be glad to know. We are about 10 times away from fatique load, using 2G as an assumption, and even that was presuming you and the bike and your missus and your luggage weighs 500kg! |

The side stand doesn't take the full weight of the bike although some people get onto them using the footpegs at shows. |

7075 T6 aluminum is excellent for that.

It is about 35-40% stronger than 6082 T6.

_________________

vince

A person who never made a mistake never tried anything new. Albert Einstein |

|

| Back to top |

|

|

SiBag

Joined: 03 Mar 2012

Posts: 251

Location: Cheshire

|

Posted: Wed Apr 10, 2013 4:37 pm Post subject: Posted: Wed Apr 10, 2013 4:37 pm Post subject: |

|

|

I have a few lumps of 2014 knocking about that should do nicely.

I thought the main advantage of the 7075 was that it was good after welding (rapid age hardening) or am I thinking of 7072 ?

I'll shut up now..

_________________

Si...

SB6..CCM R30...GSXR-750-M...RGV-250-VJ22.. GSX-1100-EFE Project....Harris Magnum II project...

If its got Ti#s or Wheels its gona give you trouble |

|

| Back to top |

|

|

Vince186

Joined: 23 Mar 2012

Posts: 636

Location: Nijmegen (Netherlands)

|

Posted: Wed Apr 10, 2013 8:10 pm Post subject: Posted: Wed Apr 10, 2013 8:10 pm Post subject: |

|

|

| SiBag wrote: |

I have a few lumps of 2014 knocking about that should do nicely.

I thought the main advantage of the 7075 was that it was good after welding (rapid age hardening) or am I thinking of 7072 ?

I'll shut up now.. |

The 2014 alu is also fine, the 2000 series is what they used in the past in aircrafts.

Only it is more sensitive to corrosion.

The 7000 series is what they use in (F16) aircrafts where the strengths are high.

For example under skin of the wing.

A disadvantage is that a scratch can become a crack. Itís that hard.

I chose for the 6000 series because itís easy to machine and still strong enough.

Has a high corrosion resistance and scratches and sharp edges are no problem.

But, I'm not a materials expert it's only what I know.

_________________

vince

A person who never made a mistake never tried anything new. Albert Einstein |

|

| Back to top |

|

|

sbbimota

Joined: 24 Oct 2013

Posts: 63

Location: santa barbara

|

Posted: Thu Oct 24, 2013 5:06 pm Post subject: Posted: Thu Oct 24, 2013 5:06 pm Post subject: |

|

|

to all....it seems to me the problem is actually where the STOP is on the sidestand, not the length. Has anyone every modified the location of the STOP so it doesn't go so far forward? when mine is at it's stopped location, the end of the sidestand (flat part where it hits the tarmack) isn't even close to parallel...

thoughts please.

Pete

_________________

pete |

|

| Back to top |

|

|

Vince186

Joined: 23 Mar 2012

Posts: 636

Location: Nijmegen (Netherlands)

|

Posted: Fri Oct 25, 2013 1:09 pm Post subject: Posted: Fri Oct 25, 2013 1:09 pm Post subject: |

|

|

Hello Pete,

Welcome to this wonderful forum.

Before my side stand modification I tried some other things to see if I could fix it without a complete new side stand.

I placed a extra washer in the pivot point to eliminate the play and placed a piece of metal between the stop and the side stand.

My findings were that the it was a little better but that when you gentle push the bike forwards it easily tipped over.

I was still not happy.

Thatís why I made a new side stand with an adjustable base so that the base always parallel is with the tarmack. (and is long enough)

P.s. pictures of your Bim are more than welcome.....

_________________

vince

A person who never made a mistake never tried anything new. Albert Einstein |

|

| Back to top |

|

|

desmopiega

Joined: 30 Oct 2013

Posts: 10

Location: rome, italy

|

Posted: Wed Oct 30, 2013 7:06 pm Post subject: Posted: Wed Oct 30, 2013 7:06 pm Post subject: |

|

|

i see that in all of the world we have this problem  |

|

| Back to top |

|

|

2bims

Joined: 03 Apr 2010

Posts: 7308

|

Posted: Wed Oct 30, 2013 10:07 pm Post subject: Posted: Wed Oct 30, 2013 10:07 pm Post subject: |

|

|

Oh its easily solved...never park facing downhill...never park on the level, or somewhere windy....always roll it back so the back wheel hits and rests against the kerb....always leave it in gear so it cant roll uphill ...always check and kick the sidestand forward and out several times just to be sure...Then tug the bars/clip ons when its rested to raise the height up....check a couple more times on the sidestand and then never stray away without someone guarding over it...Simples....  Still havent sorted my Db2 sidestand, it leans over SO SO far that the front forks pull all the way out to the stops....reassures me that at least its taking pressure off the 51mm fork seals when its resting at least...when you get on board you physically have to throw the bike to the right to get it upright...Think we should have a "funny" whats your Bimota look like when resting on its sidestand ? competition.... Still havent sorted my Db2 sidestand, it leans over SO SO far that the front forks pull all the way out to the stops....reassures me that at least its taking pressure off the 51mm fork seals when its resting at least...when you get on board you physically have to throw the bike to the right to get it upright...Think we should have a "funny" whats your Bimota look like when resting on its sidestand ? competition....

Or as its sometimes called.....Whos got the most wood????

I'll start....First with Wood or other various things easily to hand.....

Inch and a half decking slab

Purpose built Inch and a half timber cored and rubber based for ease of carrying and portability

Spare Bathroom tile (2 No), 1/4 inch///wholly inadequate, slippy surface and way too thin (early trial and error)

Days out and about and at home before I had cut up many handy chocks to leave at many various locations....

And the best till last....How I found her 3.5 years ago now...and how she had stood completely untouched and never moved for over 7 years in an underground carpark of a block of flats in London....hence why I've learnt to trust said ridiculous angle of lean.....

|

|

| Back to top |

|

|

|